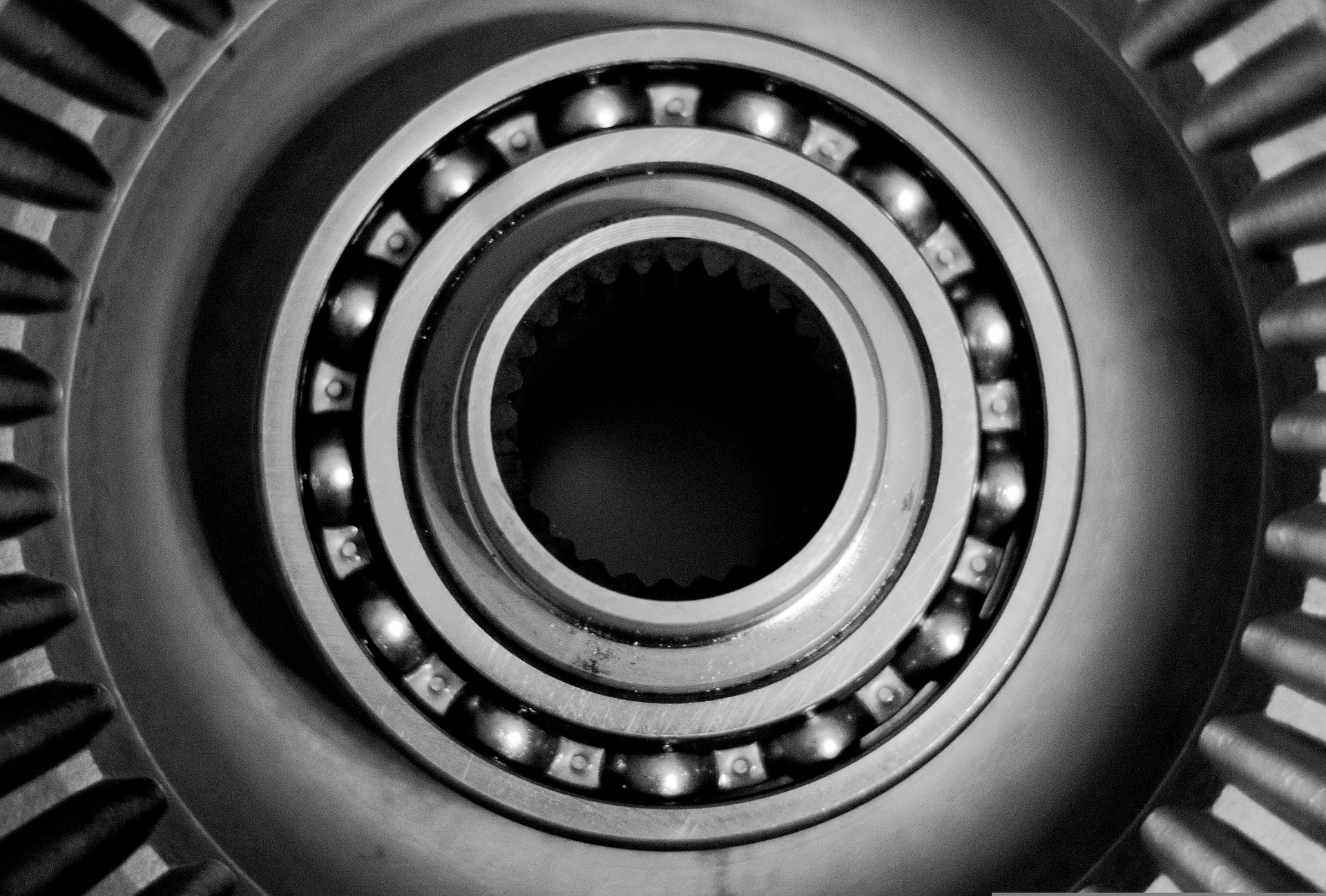

So adjustable wheel bearing lock nut wrench. I always get volkswagen cars that wheel bearing loosened. Mostly wokswagon and others have the same way of bearing nut tighten ways. Let me explain to you guys how it can be done. Bearings are adjusted by tightening the hub nut if it is too loose and loosening the nut if it is too tight. This should be done with the open wheel raised on the axle stand. Check bearing wear Rock the wheel side to side and up and down to check the bearing wear.

You may need to remove the wheel to remove the trim – reattach the wheel before beginning the setup. If it is necessary to remove the wheel. Loosen the wheel nut before lifting it. Lift the wheel and fix it on the support. Attach another wheel to each side of the car. If you are adjusting a wheel with the parking brake on. Release the parking brake.

Use two medium screwdrivers to lift the dust cover by lifting the raised flanges of the hubs on both sides. Bypassing borders can take time to break free. If it gets stuck, you can knock it out without damaging it beyond repair. But replacing the cap is inexpensive. The sleeve nut can be a serrated nut held by a cotter pin or a conventional nut under a serrated retainer held by a cotter pin. It can be an ordinary nut, which is blocked by “tapping” on its outer edge in order to distribute the metal in the slots at the end of the threaded rod.

Adjustable wheel bearing lock nut wrench – Hub nut type

Some Volkswagens have a fourth type: a threaded ring that is tightened with a nut and bolt on one side. The collar does not fit an ordinary socket wrench. But can be turned with a self-locking wrench. The sleeve nut can be serrated and held with a cotter pin. This is a regular hub nut, located under the toothed retainer.The nut has a soft outer edge which engages with a wrench in a slot in the short shaft. Some older Volkswagens used split sockets with screw-in female threads. Make sure you have a socket large enough to fit under the hub nut. If you are using cotter pins. Because you will need spare pins of the correct size. The rivet nut must be replaced each time the bearing is adjusted.

There should be some grease on the end of the axle and nut. If the bearings are very dirty, they should be removed and filled with clean grease see Wheel Bearing Removal. There are traces of metal in the bearing, it is falling apart and should be replaced immediately. If the grease seems clean, wipe it off with a rag. Because straighten the cotter pin and remove it with pliers. Discard the pin and install a new one later. Remove any tooth retainers.Using the flare nut, use a small cold chisel and hammer to tap the jet out of the shaft groove. You don’t need to remove it completely – the socket wrench has enough leverage to flatten any remaining bulges.

Using the VW clamp

Because some vehicles have left-hand threads for the proximal hub nuts, especially at the rear. Before proceeding, consult the branch. Loosen the hub nut a few turns or, if it is broken, remove it and screw in a new one loosely. If you removed the wheel, replace it temporarily, tighten the wheel nut just enough to hold it securely. Set the torque wrench to the correct hub nut number. Settings vary by boat 11 to 60 pounds per foot – 1.5 to 8.3 kg per meter and should be correct. If necessary, refer to the service manual or contact your local dealer. No need to install VW bushings with precise torque. Slowly turn the wheel in the normal forward direction with one hand and tighten the hub nut to the correct torque with the other hand.

Adjustable wheel bearing lock nut wrench – Tighten the hub nuts

Slowly turn the wheel while tightening. Finally, lower and tighten. You should feel the wheel spin smoothly, although it will start to slip as you tighten the nut. If there is actual friction or roughness, the hub bearing should be replaced. On the proximal hub nut, especially at the rear. Before proceeding, consult the branch. Loosen the hub nut a few turns or, if it is broken, remove it and screw in a new one loosely.

If you removed the wheel, replace it temporarily, tighten the wheel nut just enough to hold it securely. Set the torque wrench to the correct hub nut number. Settings vary by boat 11 to 60 pounds per foot – 1.5 to 8.3 kg per meter and should be correct. If necessary, refer to the service manual or contact your local dealer. No need to install VW bushings with precise torque. Slowly turn the wheel in the normal forward direction with one hand and tighten the hub nut to the correct torque with the other hand.

Adjustable wheel bearing lock nut wrench – Final stage

Check the specific adjustment method with the service manual or with your local dealer. Then repeat the wheel balance check. You should be able to feel the slightest cues from the game. The wheels should also continue to spin smoothly. On some vehicles including Volkswagens with hub bushings, use a screwdriver to feel around the hub nut for the thrust washer behind. If you can move the washer, the setting is correct. Lock the nut in place. The toothed nut should be moved so that one of its slots lines up with the pin hole in the end of the shaft.

Move it the shortest distance possible anyway. If you move the lock nut, make sure the wheel is still free to spin. If not, loosen the nut one click. Other types of hub nuts do not have this problem. Install tooth retainer. Insert a new cotter pin if applicable, then cut and bend the end.

So this is all i got to say about Adjustable wheel bearing lock nut wrench and adjusting the nut. I will see you guys soon with a new article.